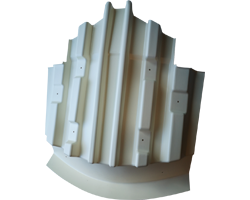

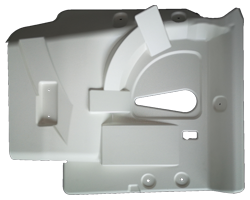

Aeronautics

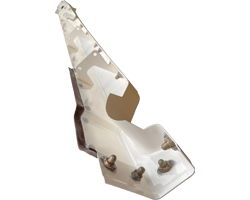

Historically a tier 1 supplier to european aircraft manufacturers and a pioneer in thermoformed interior fittings, we permanently adapt and innovate to serve a wide range of competitive applications for aircrafts, helicopters and even rockets.

In addition to our traditional aeronautical range, such as cockpit, cabin and seat trim, door trim, cable and electrical bay protection, ventilation, flash light protection, etc., our expertise will support you in the design and implementation of your new projects.

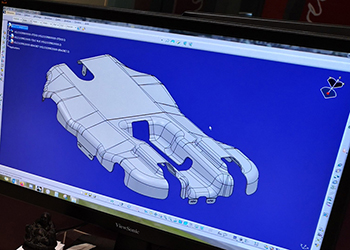

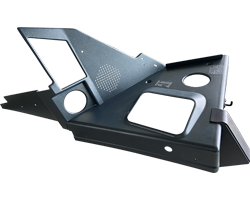

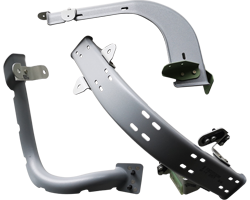

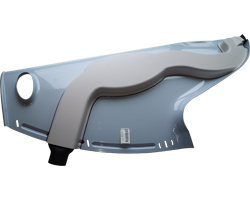

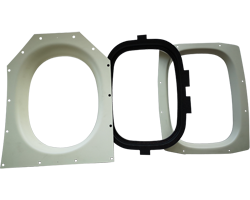

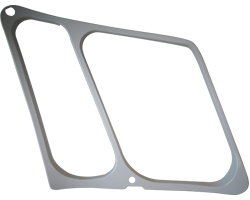

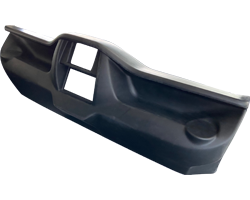

Vehicles

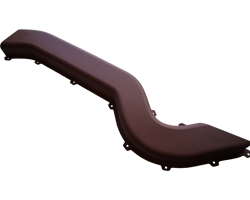

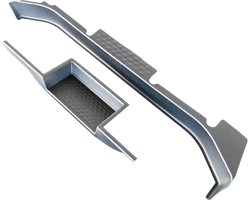

By precisely adjusting to the requirements of industrial customers, Soplami offers high-performance thermoformed interior and bodywork solutions for leisure vehicles, commercial vehicles, agricultural vehicles, electric vehicles, mass transport and new mobility.

Color and surface finishes counter-typing, co-extruded materials, co-design... we deliver complete panoplies consisting e.g. of door trim and interior panels, door threshold, shower tray, dashboard, rear bumper, doors and vehicles front parts...

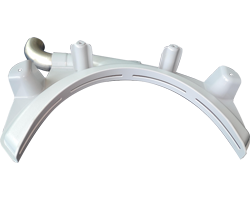

Medical

Offering thermoformed, laser or flat-machined sets, screen printing, digital printing, anti-bacterial materials, we meet the needs of medical equipment manufacturers by ensuring an optimal finish.

We support you in medical and paramedical fields, hospital equipment, laboratory devices, personal care, physiotherapy equipment, orthopedics, distribution trolley, presso-therapy, research, health, sports and well-being equipment.

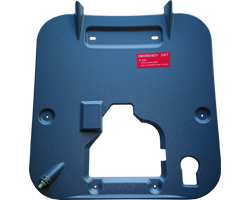

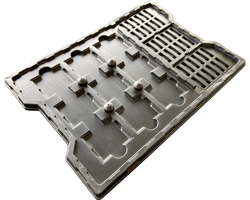

Industry

With complementary production means like hot and cold folding, PMMA forming... we support start-ups and SMEs for a wide variety of bespoke projects in unitary, small or medium series, with design and materials creativity.

Beside our manufacturing range for POS, interior architecture, building, sports facilities, we contribute to your innovations with transparent parts, industrial cowls, attractive design hoods for electronic devices...